Dubai Engineering delivering high quality, cost effective solutions for the oil & gas, Metal, Packing, food, pharmaceutical and power industries.

Our reputation for safely delivering quality projects on time and on budget is well recognized in the industries we serve. We have proven expertise in managing large, complex projects, a global reach and longstanding market presence, strong relationships with our clients and cutting-edge processes and technologies.

|

The following are some of projects were done in the UAE 2004/2005 |

DUBAI TOWN WATER PUMPS UPGRADE:

|

| Installation, commissioning of two Pumps of 444 Liter/ Sec., two motors and two Variable Frequency Drives 320 KVA |

|

Electrical Installation, Programming and Commissioning, in the MCC |

|

Mechanical and Instrument Installation:

|

|

Construction of process lines, Instruments erection, installation and calibration, Pump and motor installation, alignment

|

|

Planned Procedure of installations to do the required scope of work, in the earliest time with all required specifications.

|

|

Dubai Engineering has a well trained qualified team, who can do all the professional jobs to satisfy client requirements. |

Dubai Engineering finished project, doing functional test, start up, and test run for 72 hours |

|

Project in Final Situation |

|

|

The Motor and Pump are running |

|

|

NATIONAL STEEL FACTORY : |

Upgrade of Schlatter (Switzerland) Steel Mesh Welding Machine Control System.

Machine Control System was changed from old type which caused many problems for operation and maintenance, too much trip shutdowns and slow production, to a new control system with PLC which is much faster, reliable, user friendly with advanced operating Options. |

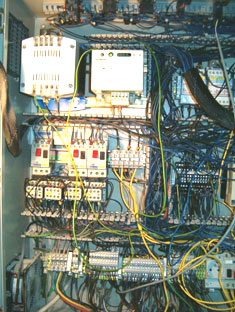

The following photos are for the old Control panel of machine before Upgrade: |

|

|

|

| The following photos are Machine Control System after upgrade: |

|

|

A complete new designed PLC control panel, with configuration software was done, to replace completely the old conventional relay controlled panel. |

After running of the new control system:

- The production rate increased three times than before.

- The machine operators decreased from five to two operators.

- The product quality is much better than before.

- The shutdowns, and maintenance time much less than before.

|

|

ALPHA WATER PROJECT: |

Upgrade of UROLA filling Line Control System

Machine Instruments and Control System were changed from old type which was causing many problems, too much trip shutdowns and slow production, to a new control system with Siemens S7 PLC which is much faster, user friendly and includes Advanced Operating Options.

|

|

|

Electrical panel before upgrade |

Implementation of a new control system with PLC |

|

|

Programming, commissionning

& start up. |

Testing before start up |

|

|

Doing functional Tests for the Machine |

Machine running at optimum performance. |

|

|